DIY Storage Building Cost Calculator

DIY Cost Estimate

$0

Pre-Built Kit Price Range

$2,000 - $2,800

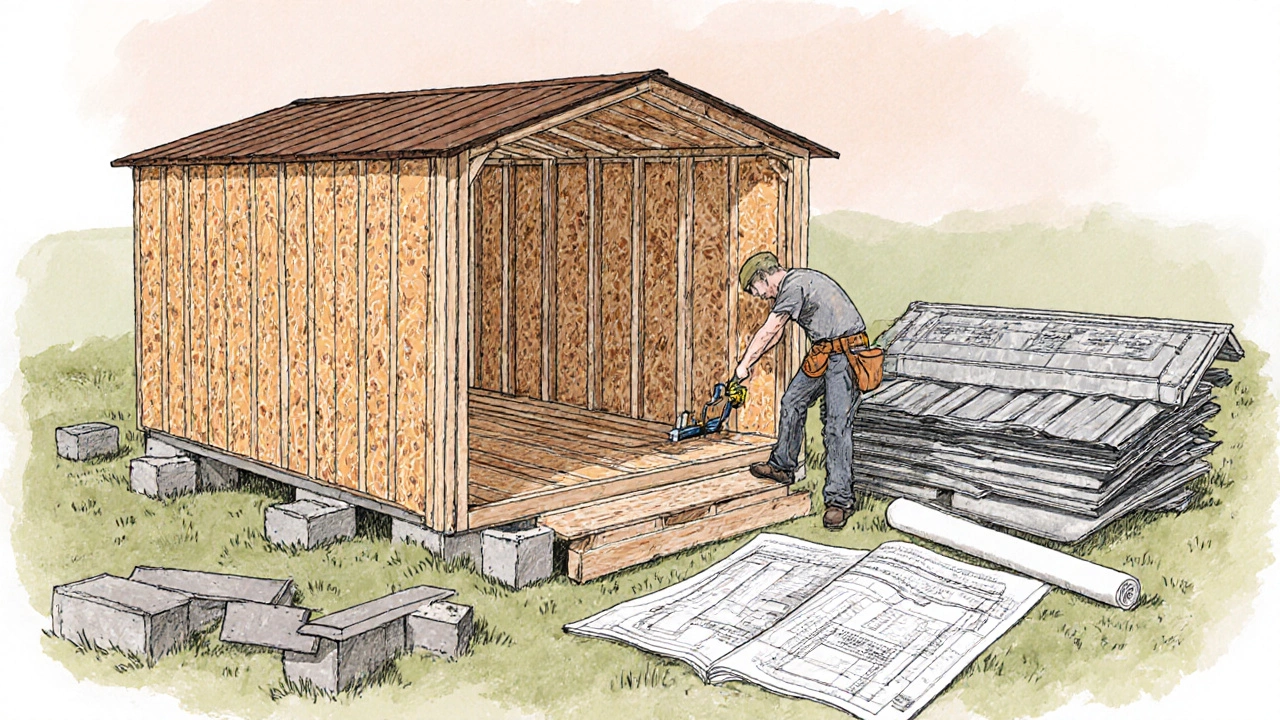

Ever wondered whether rolling up your sleeves and constructing a DIY storage building will actually cut costs compared to buying a ready‑made shed? The answer isn’t a simple yes or no-it hinges on materials, permits, labor, and the level of finish you need. Below we break down every cost factor, give you a step‑by‑step budgeting worksheet, and help you decide when a do‑it‑yourself project makes sense.

Key Takeaways

- Materials typically account for 55‑70% of total DIY costs; labor is the biggest savings driver.

- Permits and site preparation can add $200‑$800, sometimes erasing the DIY advantage.

- For a 10×12‑ft shed, DIY builds average $1,200‑$1,600, while pre‑built models range $1,800‑$2,500.

- Complex roofs, insulation, or custom windows push DIY costs above off‑the‑shelf prices.

- Plan carefully, source bulk lumber, and rent tools to maximize savings.

Understanding the Central Entity: Storage Building

Storage building is a standalone structure designed to hold tools, seasonal items, or bulk goods. It can be freestanding or attached to a house, and options range from basic metal kits to fully insulated wooden cabins. Typical dimensions run from 6×8ft for garden sheds to 12×20ft for workshop‑sized units. The primary purpose is to protect belongings from weather, pests, and theft.

Primary Cost Drivers

When you compare a DIY build to a pre‑built shed, focus on four cost buckets: materials, labor (or saved labor), permits, and ancillary expenses.

1. Materials - The Backbone of Your Build

Lumber serves as the structural skeleton for most wooden storage buildings. Pressure‑treated 2×4s for framing cost about $3‑$4 per linear foot, while premium cedar runs $5‑$7. For a 10×12ft shed, you’ll need roughly 150linear feet, translating to $450‑$1,050 depending on grade.

Concrete foundation provides a level, moisture‑resistant base. A pre‑mixed slab can be poured for $5‑$8 per square foot, so a 120‑sq‑ft footprint costs $600‑$960. If you opt for concrete deck blocks, the price drops to $1‑$2 per block, totaling $120‑$240.

Roofing material choices affect both cost and durability. Asphalt shingles average $30‑$50 per bundle (covers ~33sqft). Metal panels cost $1.50‑$3.00 per square foot installed. For a 12‑ft‑wide roof, expect $360‑$720 for shingles or $540‑$1,080 for metal.

Insulation is optional for basic storage but essential if you plan to use the building as a workshop. R‑13 fiberglass batts run $0.45‑$0.60 per square foot. Adding insulation to walls and the roof can add $150‑$300.

Design plans streamline material estimates and reduce waste. Professional plans sell for $30‑$120, while free DIY kits are abundant online.

2. Labor - Where DIY Saves Money

If you hire a contractor, labor alone can be $35‑$70 per hour. A typical 40‑hour build costs $1,400‑$2,800. Doing the work yourself eliminates that line item, but you’ll need to account for your own time and any learning curve.

3. Permits - The Hidden Expense

Most municipalities require a building permit for structures over 100sqft. Permit fees vary by city, ranging from $50 for a simple garden shed to $300‑$800 for larger, insulated units. Some areas also demand inspections, which can add $100‑$200.

4. Ancillary Expenses - Tools, Fasteners, and Finishes

Tool rental can be a smart way to avoid buying expensive equipment you’ll use once. A nail gun, circular saw, and compact excavator typically cost $150‑$250 for a weekend.

Fasteners (galvanized nails, screws, joist hangers) usually total $100‑$150. Exterior finish-paint or stain-adds $80‑$150.

Cost Comparison: DIY vs Pre‑Built

| Component | DIY (Low‑End) | DIY (High‑End) | Pre‑Built Kit |

|---|---|---|---|

| Lumber & Framing | $450 | $1,050 | - |

| Foundation | $120 (deck blocks) | $960 (slab) | - |

| Roofing | $360 (shingles) | $1,080 (metal) | $800‑$1,200 |

| Insulation (optional) | $150 | $300 | - |

| Permits & Inspections | $200 | $800 | Included in price |

| Tools & Fasteners | $250 | $350 | Included |

| Labor | $0 (self‑done) | $0 (self‑done) | $0 |

| Total Estimated Cost | $1,530 | $4,540 | $2,000‑$2,800 |

As the table shows, a low‑budget DIY build can undercut a pre‑built kit by $400‑$800, but the high‑end DIY scenario quickly surpasses store‑bought prices. The sweet spot is a modest‑grade lumber, concrete deck blocks, and asphalt shingles-roughly $1,500 total.

When DIY Makes Financial Sense

- Small footprint: 6×8ft or 8×10ft structures keep material volumes low.

- Basic roof: Simple gable or shed‑style roofs avoid expensive trusses.

- No insulation: If you’re just storing garden tools, you can skip the $200‑$300 insulation line.

- Access to bulk lumber: Buying from a wholesale lumberyard saves 10‑15% versus retail.

- Tool ownership: If you already own a circular saw and drill, you eliminate rental costs.

When a Pre‑Built Shed Is the Smarter Choice

- Regulatory hurdles: Cities with strict building codes may require engineered frames that are costly to engineer yourself.

- Time constraints: A pre‑built kit can be assembled in a single weekend, whereas DIY may stretch over weeks.

- High‑end finishes: If you need insulated walls, double‑wall framing, or custom windows, manufacturers already factor those costs into a competitive price.

- Limited DIY experience: First‑time builders often underestimate waste and end up buying extra material.

Step‑by‑Step DIY Budget Worksheet

- Define dimensions & purpose (e.g., 10×12ft, tool storage, no insulation).

- Check local building codes. Note permit fee and required setbacks.

- Choose foundation type: deck blocks vs poured slab. Record unit cost.

- Create a material list:

- Lumber (2×4, 2×6 for walls, rafters).

- Sheathing (OSB or plywood).

- Roofing (shingles or metal).

- Fasteners (galvanized nails, deck screws).

- Optional: insulation, exterior paint.

- Price each line item at your preferred supplier. Add 10% contingency for waste.

- Enter permit costs and any professional plan fees.

- Calculate tool rental if needed.

- Total the numbers. Compare against three pre‑built kits of similar size.

If DIY total ≤ 85% of the lowest kit price, you’re likely saving money.

Common Pitfalls and How to Avoid Them

- Under‑estimating waste: Always add a 10‑15% buffer for cut‑offs and mistakes.

- Skipping the permit: Getting fined later can wipe out any savings.

- Buying cheap lumber: Low‑grade wood can warp, leading to costly repairs.

- Rushing the foundation: An uneven base causes door/frame misalignment and water intrusion.

- Ignoring weather windows: Plan your build for a dry season; moisture delays add hidden labor costs.

Real‑World Example: Jane’s Backyard Workshop

Jane lives in a suburb of Denver. She needed a 10×12ft space for woodworking tools. After a permit fee of $250, she chose deck blocks ($150) and pressure‑treated lumber ($800). She used asphalt shingles ($400) and skipped insulation. Tool rental cost $180. Total: $1,780. The nearest pre‑built metal shed of similar size was $2,300, plus delivery ($250). Jane saved $770 and finished the project in 5 days. Her only regret? She didn’t budget extra for a small concrete pad to level the floor, which she added later for $120.

Bottom Line: Do the Math Before You Pull the Nails

If you have the time, basic carpentry skills, and access to discounted lumber, building your own storage building can shave a few hundred dollars off a comparable pre‑built model. However, the margin narrows quickly once you factor in permits, higher‑grade materials, or a need for insulation. Use the worksheet, check local regulations, and weigh your own labor value. The decision isn’t just about price-it’s about how much effort you’re willing to invest for that extra dollar saved.

Frequently Asked Questions

Do I need a building permit for a small storage shed?

Most U.S. cities require a permit for structures over 100sqft. Even a 6×8ft shed can trigger a permit if it’s attached to a house or includes electrical work. Check your local building department; fees typically range from $50 to $300.

What’s the cheapest foundation option?

Concrete deck blocks are the most economical, costing about $1‑$2 each. A 10×12ft shed needs roughly 12‑15 blocks, totaling $120‑$240. They’re quick to install and work well on level ground.

Can I use reclaimed wood for the frame?

Yes, reclaimed lumber can lower material costs and add character. Just inspect each piece for rot, split, or nail holes. Ensure the wood meets structural requirements-use it for non‑load‑bearing parts if you’re unsure.

How much time should I budget for a DIY build?

A straightforward 10×12ft shed usually takes 30‑40 labor hours for an experienced DIYer. If you’re learning as you go, plan for 50‑60 hours spread over a weekend and a few evenings.

Is it worth insulating a storage building?

Insulation adds $150‑$300 and boosts comfort if you plan to use the space year‑round for a workshop. If the building is solely for dry storage, you can skip insulation and save money.